Bristol-based

MACH Machine Tools, part of the

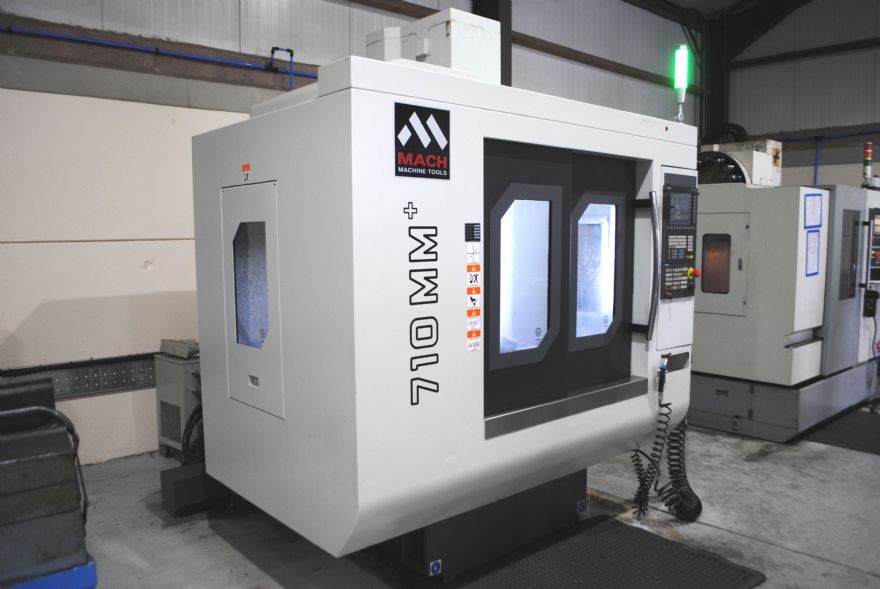

Vigilance Group, has supplied Aluminium Extrusion Tooling (AET) Co Ltd in Gloucester with a new MACH 710MM+ vertical machining centre.

The machine, which was installed in July 2019 at AET’s newly established production facility in Staunton, has been used to machine high-precision customised hollow, semi-hollow and solid extrusion dies for its growing UK and international customer base.

The company supplies extrusion dies into a growing number of industrial sectors including building/construction, transportation, automotive, consumer goods, electrical and energy.

The extrusion dies can be made in a virtually limitless variety of shapes and sizes and are machined from H13 tool steel, This involves a number of machining methods and processes including milling, wire and die-sink EDM and secondary finishing operations prior to being heat-treated (48HRC) for the final time and assembled ready for despatch.

Completed die sets, or die stacks, comprise a number of different components including die rings, mandrels, mandrel holders, stems, dummy blocks and bolsters.

All component parts are machined to high accuracy and surface finish and many, especially those used in hollow dies, have complex profiles and geometries with intricate details and features.

AET manufactures a range of different diameter dies from 105 to 550mm diameter — the MACH 710MM+ is being used to machine the smaller- to medium-size dies with the average size being 260mm.

Lead times for delivery depend on the complexity of the die, and the customer, but the typical lead time for more straightforward dies is seven days — with three weeks being the average for more complex ones.

Prior to the Covid-19 outbreak, AET manufactured around 120 dies per month, but since then demand has inevitably dipped slightly. However, the company’s commitment to quality, lead time fulfilment and cost control have ensured that AET has won new orders during this period and also strengthened its position as a premier extrusion die manufacturing specialist.

The MACH 710MM+ acquired by AET is a compact, high-performance three-axis vertical machining centre with X/Y/Z travels of 710 x 400 x 450mm. It has a chilled direct-drive 19kW/8,000rev/min BBT40 face and taper spindle, a large 850 x 410mm working table which can accommodate up to a 300kg maximum table load, a rapid-change 24-position automatic tool changer and a Siemens 828D control with ShopMill conversational programming software included.

It is fast (48m/min) and, to ensure impressive accuracies and surface finishes, has a Meehanite construction and heavy-ribbed column design as well as linear guides on all three of its axes.

AET’s director Lee Knight said: “We are in a competitive global industry, and as a relatively new company it is important that we invest in advanced and proven machine tool technologies to ensure that we can meet customers’ quality requirements and delivery schedules and at the same time be cost-competitive.

“The MACH 710MM+ has proven to be a technically excellent machine and is fast, accurate and reliable — all key performance attributes. We are particularly impressed with the machine’s smooth and responsive acceleration and deceleration, and its ergonomic design that provides greater operator access to the machining area.”

In addition to its performance, another positive for AET was that the machine was immediately available from stock and that it could be acquired on a three-year MACH Hire lease contract.

Ashley Jones, AET’s production manager, said: “For a new start-up like us, the MACH Hire arrangement was attractive and made economic sense. With cashflow being a particular and pertinent consideration, the MACH Hire facility meant we could get the machine without paying a deposit up front and that the agreed monthly fee was fixed over the duration of the term and included annual service costs and extended warranty cover as well as machine tool delivery, installation, commissioning and training.”

Although the pandemic has ‘turned things upside down’, AET is confident about the future. It has recently invested in a large-capacity vertical machining centre with X/Z travels of 1,000/600mm from

Machine Tools Sales Online) — also part of the Vigilance Group — to machine larger diameter dies up to 500mm.

Mr Knight concluded: “Despite the pandemic the advanced machine tools we now have at our disposal makes us ideally positioned to capitalise on the upturn.”