Birmingham based CNC Routing Ltd is stepping up to support the NHS and critical infrastructure during the coronavirus pandemic with the help of its supplier Tamworth-based cutting tool specialist Industrial Tooling Corporation (ITC —

www.itc-ltd.co.uk).

Founded in 2005, CNC Routing (

cncroutingltd.co.uk) employs 26 people and serves the automotive, retail, healthcare and industrial sectors with its design, routing, finishing, fabrication, installation and building services.

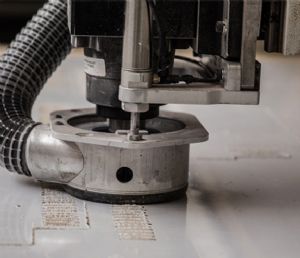

The company has three AXYZ rotating machines, each having a twin-head facility and when one of its customers became lend a hand.

Chris Noble, CNC Routing head of design and technical, said: “We were commissioned to manufacture 8,000 acrylic, PETG and polycarbonate ‘sneeze screens’ for supermarket checkouts. Machined from 3,050 x 2,050mm sheets, they are manufactured in two sizes, 600 x 750mm and 750 x 1m, with panel thicknesses ranging from 3 to 6mm.

“With the screens being supplied to more than a dozen supermarket chains, each with various till and checkout dimensions, the different sized screens require both hole position and dimensional variations.

“This has resulted in our company producing more than 12 different screen variants.”

As soon as the contract was agreed, the company placed an order with ITC and 60 cutting tools were duly delivered the next morning.

Mr Nobile continued: “We have been successfully working with ITC for over 12 years and they supply all the cutting tools for machining our plastic components. The service, support and technical advice is only surpassed by the quality of its cutting tools.”

“From a technical perspective, we were having problems some years ago with our cutting tools gripping parts and lifting thin sheets from the vacuum bed of the AXYZ machines during processing.

“ITC provided first-class technical support by investigating our existing tools, materials and cutting parameters, and subsequently supplying new tools and machining strategies that resolved the issue.

“Since then, we have had every confidence in ITC.”

Observing UK Government safe working guidelines, CNC Routing has moved many of its office-based staff to homeworking while the factory has changed from a two-shift to a three-shift pattern to accommodate the new work.

Mr Noble added: “As a business we are conscious of the health and safety of our staff, and all employees are provided with suitable PPE and by moving to 24-hour production with three shifts, our shopfloor staff levels have been naturally reduced.

“Furthermore, each of our three AXYZ routing machines are 3m apart, so our factory floor automatically exercises social distancing.”

From a production perspective, CNC Routing has one AXYZ router with bed dimensions of 4,880 x 2,635mm and two further machines having a slightly smaller bed. This enables the company to place four 8 x 4ft sheets on the machine bed at any one time.

Mr Noble explained: “Each machine incorporates a twin cutting head, which we can set at different widths. For the ‘sneeze sheets’, we have spaced the cutting heads at a distance of 1,230mm apart, so we can cut two sheets simultaneously.

“With three twin-spindle routers running 24hr a day, the performance and reliability of the ITC solid carbide routing tools is essential.”

CNC Routing Ltd placed an order for sixty 180-2362-10-E 6mm Clearcut Series single flute routers from ITC to fulfill the sneeze screen order.

Mr Noble said: “From experience, we know that these tools perform really well, have exceptional tool life and with the upward spiral flute geometry are perfect for machining thin sheets without lifting from the vacuum bed.

“This confidence in the 180 Clearcut Series has been confirmed, as we have run the tools at 24,000revs/min up to the full 6mm depth of cut at cutting speeds of 7m/min.

“These machining parameters are beyond the recommended cutting conditions, but extraordinary times call for extraordinary measures.

“Luckily, the quality of the ITC Clearcut Series can handle the increased speeds and feeds with ease.”

“Despite running at significantly increased machining parameters, the 6mm diameter tools can comfortably process more than 50 sheets before we have to change the tool.

“After cutting 50 sheets, the cutting performance and edge finishes are as good as they are on the very first sheet that we cut with a new tool.

“The only reason we change the tools after machining 50 sheets is because the protective film over the acrylic, PETG and polycarbonate ‘sneeze screen’ sheets begins to fray slightly and ‘fluff up’.”

Mr Noble concluded: “As the longevity of this situation continues and ‘non-essential’ retail companies re-open their doors for business, we expect to be making these sneeze screens for many different retail outlets.

“Added to this, we also have a healthy order book with the healthcare sector for furniture and storage units. We can do this as our regular retail work is naturally ‘on-pause’.”