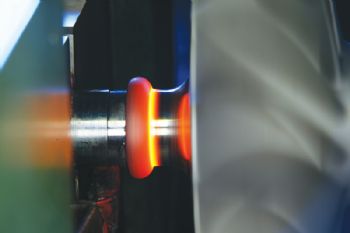

A Black Country manufacturer has won an order for a 50-tonne friction welding machine from a US engineering company.

Wisconsin-based American Friction Welding is North America’s largest direct-drive rotary friction-welding

sub-contractor. It will use the machine from Halesowen-based Thompson Friction Welding to join a wide variety of components up to 8ft in length (

www.thompson-friction-welding.co.uk).

The single-ended machine, which features Thompson’s latest software and human-machine interface, plus new controls and hydraulics, will extend AFW’s capabilities for friction-welding products that are typically used in the semiconductor, defence, electrical and aerospace industries.

It features include a self-centring clamp, a manual positional back-stop, part orientation and an adaptive forge function for accurate length control, plus a single-tool two-axis flash removal system.

It will bring the number of Thompson friction welders in use at AFW’s facility to nine.

AFW president John Fischer said: “As a quality- and technology-driven company, it is important to maintain a competitive edge by having up-to-date equipment that not only increases our capacity but also shortens lead times for customers.

“Thanks to its on-going commitment to innovative technology and proven reliability, Thompson remains an invaluable supplier.”